If you are someone who is now in the market for some mountain bike suspension forks and want to know what the best ones out there are, then you have come to the right place. Purchasing a new suspension fork for your mountain bike is definitely one of the most expensive things that you’ll be […]

Bike Advisor

Bike Advisor; the latest addition to Gadget Advisor contains the latest news from the bicycle market and industry, riding advice, maintenance and service tutorials, bike reviews and much more.

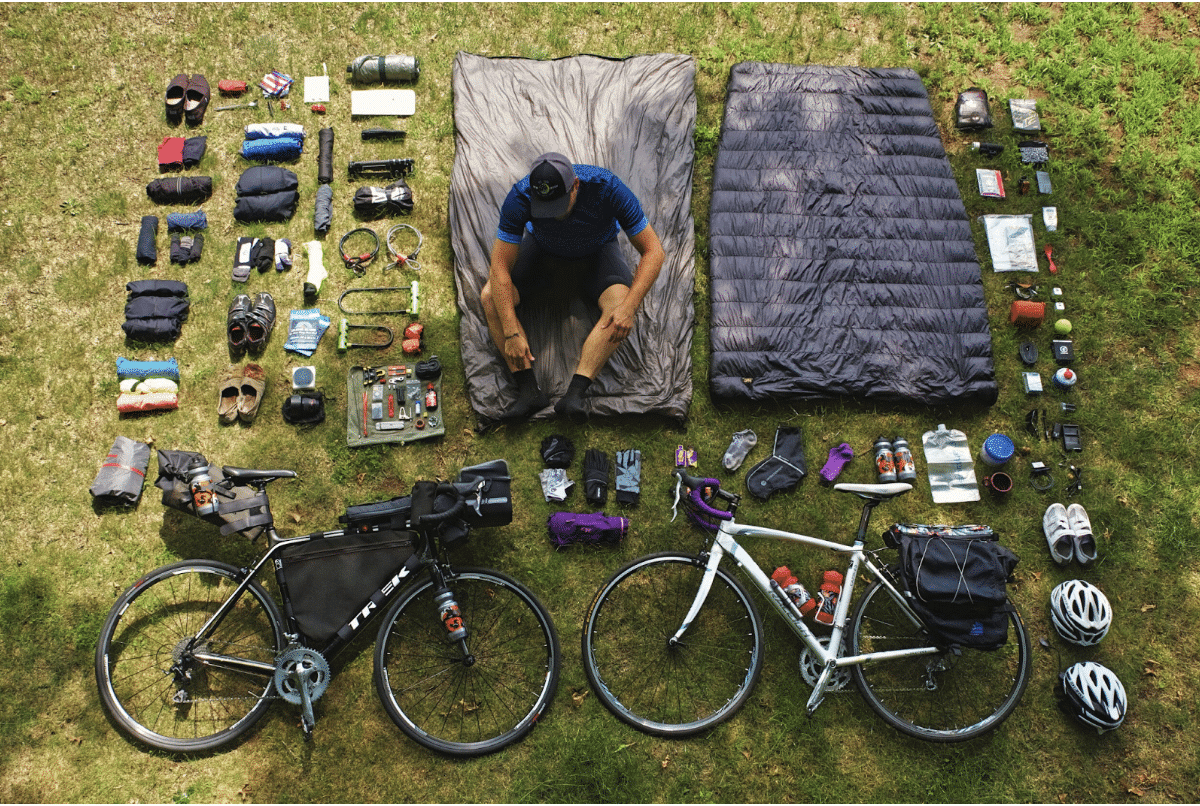

The Best Gifts for Cyclists in 2024

If someone close to you is passionate about cycling, you likely know it’s a sport that often involves a constant desire for new gear. The allure of shiny, new equipment holds almost as much sway over cyclists as the sheer thrill of hitting the road on their bikes. So, in this article you’ll get a […]

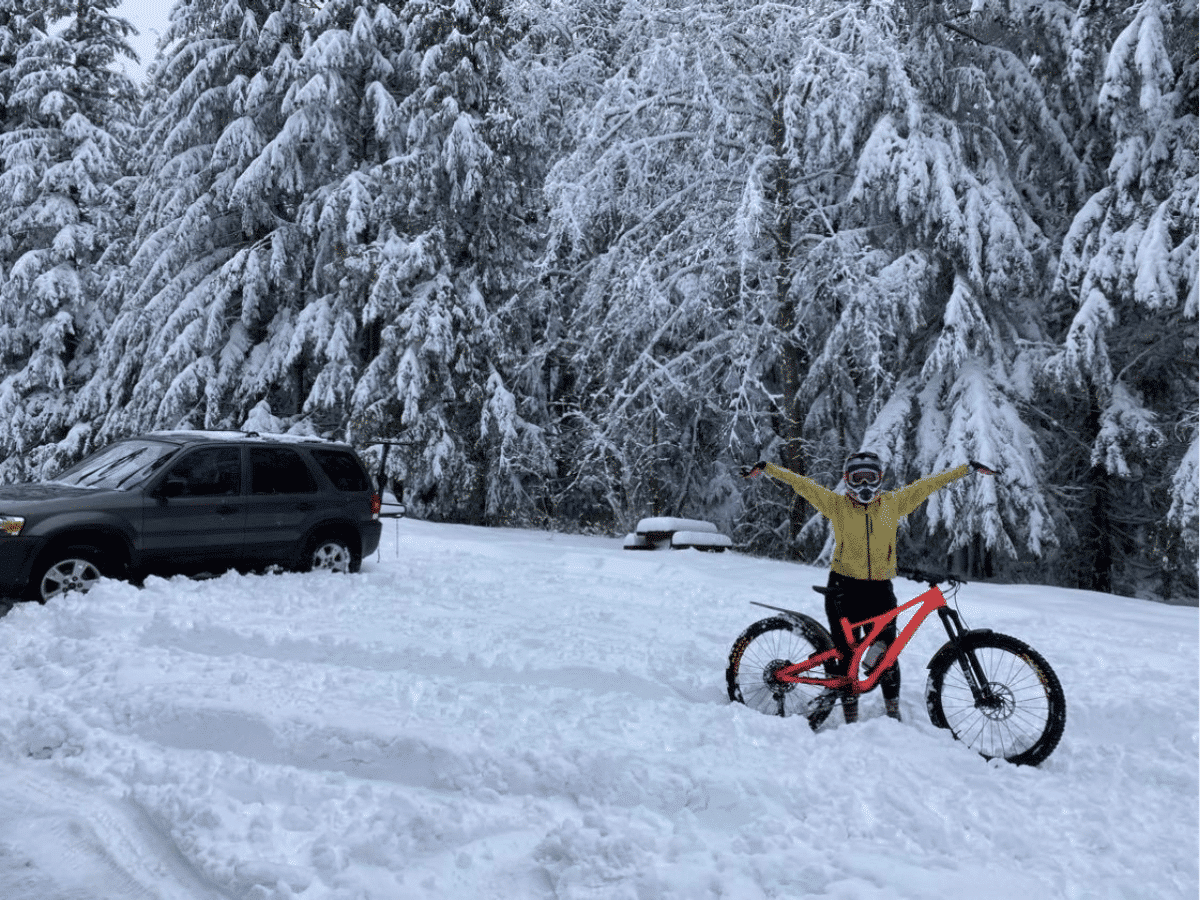

Full Guide To Preparing Your Mountain Bike For Winter Riding

When it comes to mountain biking in the winter then you need to be careful because the rainy and muddy winter weather can cause issues for your mountain bike, leading to wear, parts seizing, or decreased performance compared to other seasons. Here are some helpful tips to winterize your bike, ensuring better rides and simpler […]

A Complete Guide To Preparing Yourself For Mountain Biking in The Winter

Winter mountain biking might seem daunting initially, especially with the added hassle of donning waterproof gear and frequent bike clean-ups, leaving many yearning for warmer days. Yet, there’s a side to it that offers the most fulfilling rides of the year. Trails dusted with snow and layered with muddy roots take on a new dimension […]

Cool Bike with Mandalorian Theme

GT has collaborated with the Star Wars team, and the result is a Mandalorian version of their Pro Performer 29. The base is a silver-colored variant of the model, which has then been adorned with leather details, and some parts have been made in blue anodized aluminum. I think the result is really stylish, and […]

Best Headphones For Riding In 2024

The best headphones for cycling won’t just be the same as the best headphones as these headphones need to be able to let you enjoy your favourite music on your bike, without putting you in any sort of danger from traffic or other hazards you may encounter. Cycling with headphones in is definitely a very […]

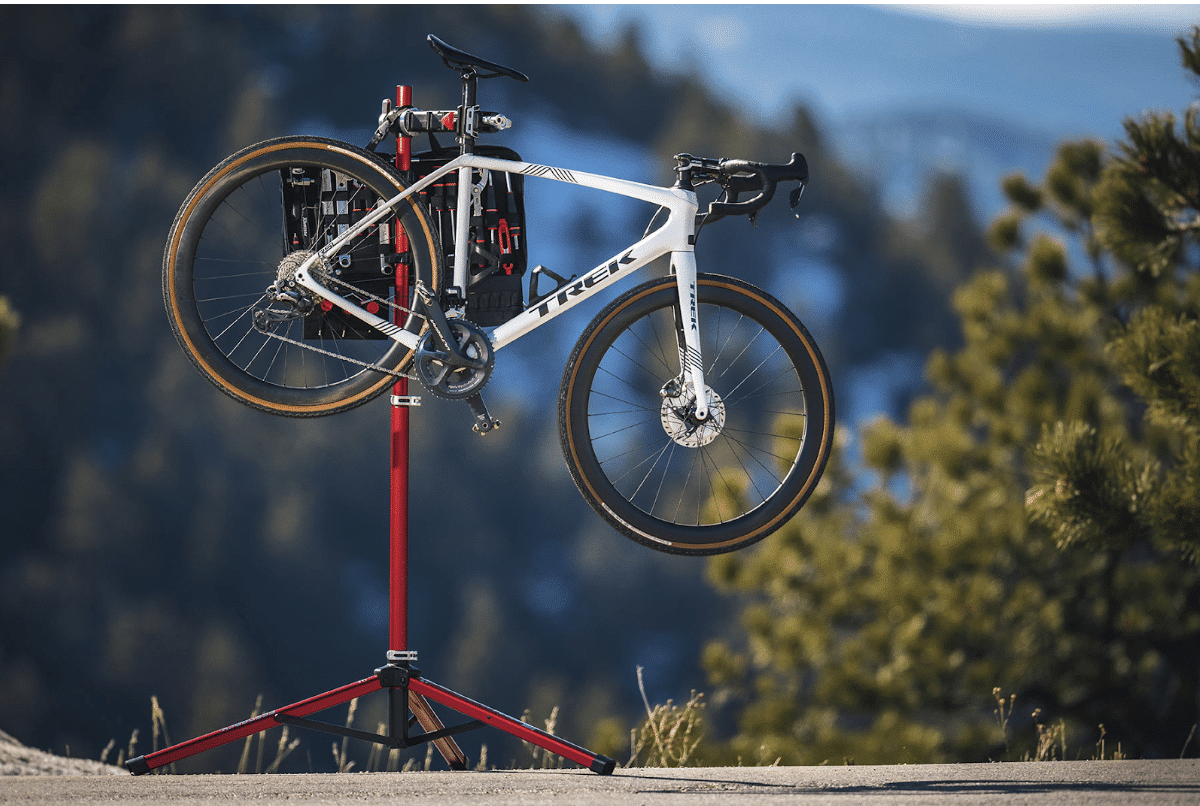

The Best Bike Repair Stands

Having a quality bike repair stand or workstand is crucial for anyone performing maintenance or repairs on their bike. It provides a stable and convenient platform to securely hold the bike, allowing for easier access to various parts and components during maintenance tasks. Whether it’s simple adjustments, cleaning, or more complex repairs, a reliable bike […]

The Best Dropper Posts

For those cyclists and mountain bikers that don’t know what a dropper post is, you’re in for a real treat. A dropper post is what we call a telescopic seatpost that has the ability to lower your saddle out of your way by just the tap of a button. This means that you won’t have […]

New Lavish Bicycle from Aston Martin

Aston Martin’s latest creation has just two wheels. Technically, it’s a bicycle from J.Laverack that Aston Martin has collaborated on. However, they are making a big splash, describing it as “The world’s most bespoke, advanced, and meticulously engineered road bicycle.” The name of this bicycle is J.Laverack Aston Martin .1R, and it features a carbon […]

A Look At The New Nukeproof Megawatt With A Full Carbon Frame

The all new Nukeproof Carbon is essentially a carbon-framed version of allot Megawatt, which was arguably the best eMTB Bike of 2022. A huge contributing factor to this bike seeing so much fame is because it was one of the first bikes to ever use SRAM’s new Eagle Powertrain motor system. This new Nukeproof bike […]

How to Fit and Set-Up Tubeless Tyres – A Step-By-Step Tutorial

Before even starting to set up your tubeless tyres on your bike, it is really important to first make sure that you have all of the components needed to do the job so that you don’t get halfway and then realise that you can’t finish it. Now that you have made sure that you have […]

Everything You Need To Set Up Tubeless Tyres

Tubeless tyres are just getting more and more popular over the years and for some really great reasons as well. One of the most important benefits that you get from running a tubeless tyre on your bike is that you will be able to run at lower tyre pressures, which as a result will lead […]

The best gravel wheels in 2023

When it comes to the best gravel wheels that you can purchase in 2023, they’ll have to be light, stiff and durable. These types of wheels have been specifically built to withstand the rough terrain from the mixed surfaces that you may be riding on. These wheels have also been designed in a way such […]

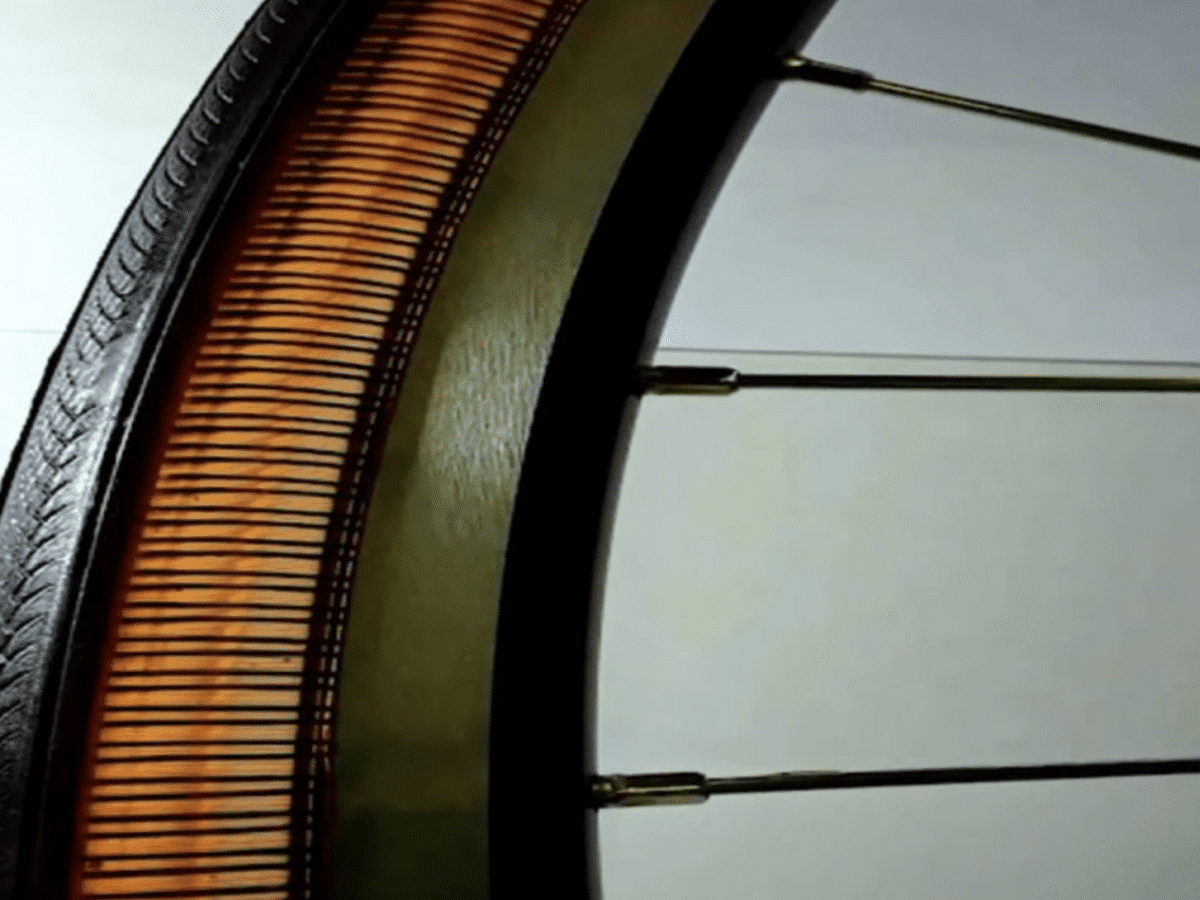

Now you can purchase the puncture-proof bicycle tires Metl

The American startup Smart Tire Company has started taking orders for the puncture-proof bicycle tires it unveiled two years ago. The tires are called Metl and are developed using similar technology to what NASA uses for the tires on its Mars vehicles. Inside the Metl tires, there is a ring-shaped spring, as seen in the […]

Understanding Cranksets

One of the most important parts of your bicycle, and arguably the heart of any bike, is the crankset, also known as a chainset. The crankset is one of the most crucial components that help move the chain as you’re pedalling. This guide will include all the information that you may need to know about […]

The Different Crankset Types

Cranksets are a really important part of your bike and may very well be the most important part as it is the thing that allows your bike to move forward. The various crankset designs out there will differ from one another depending on the type of riding that they have been designed for. In this […]

A Full Buyers Guide To Bike Pumps

Knowing exactly how to pump up your bike’s tyres is an essential skill that every single cyclist should know, and having a bike pump is one of the first tools that you should purchase if you’re looking to do your own bike maintenance and not bring it to someone else or a shop whenever something […]

Best Mini Bike Pumps in 2023

This article is for those riders out there that are in the market for a new mini bike pump, or their very first one. In this article you’ll see some of the best mini bike pumps that you’ll be able to get your hands on in 2023, as well as information on them, to help […]

The Best CO2 Inflators For Your Bike

If you’re out, in terrible winter weather, with a flat tyre or a puncture and are in a hurry to get out of there, CO2 inflators become your best friend. A CO2 inflator is a pressurised canister of carbon dioxide gas, and when it is pierced into your tyre, the gas expands to fill up […]

Best Floor Bike Pumps

In this article you’ll get a full list of some of the best, most reliable and durable pumps that there are in 2023. It’s a good idea for each rider to at least have one decent floor pump at home, and if you’re planning on building anything like a home workshop then it should be […]

The Best indoor Cycling Apps

Although it is almost a guarantee that most riders would prefer to ride their bikes outside, there are indoor cycling apps that are out there that can help you get fitter and faster, when the weather or your life stops you from getting out of the house. Even though these apps don’t exactly replicate the […]

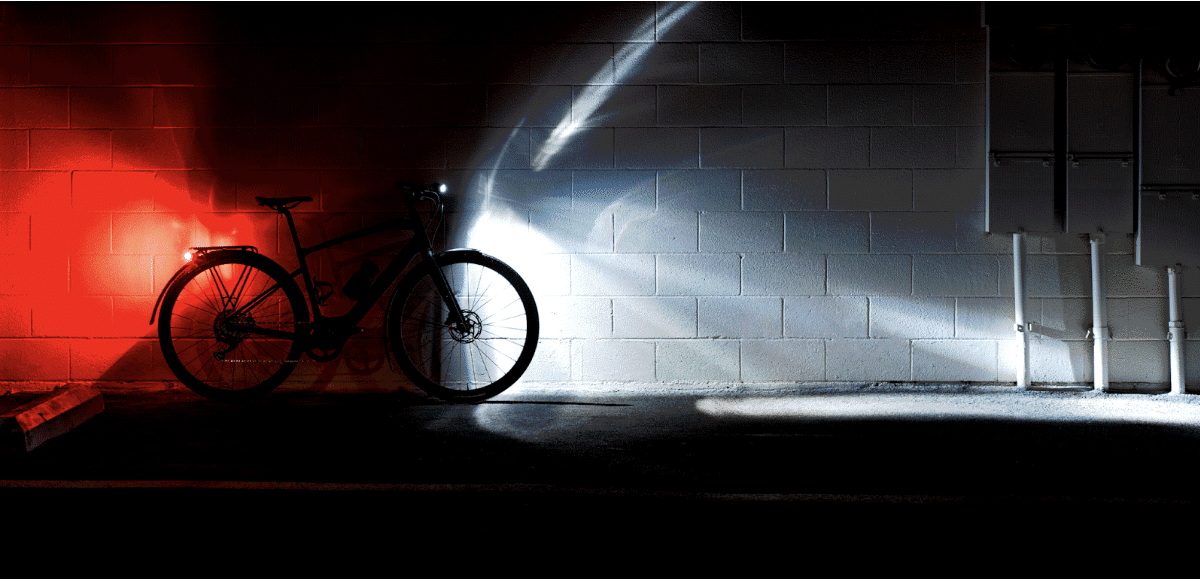

Full Guide to Buying Bike Lights

Having bike lights on the front of your bike, and sometimes in the rear, is quite important not only to make the path ahead of you more visible but to also make yourself visible to traffic and others. For those who are picking their first bike light to add to their setup, there are a […]

The Best Bike Lights for Road Cycling and Commuting

A great set of bike lights should be one of the first accessories that you purchase for your bike. As you probably already know, cycling lights are essential for cycling during the night, or anytime that you experience poor visibility. In some places, such as the United Kingdom, it is actually a legal requirement to […]

Guide To Purchasing The Best Mountain Biking Pedals For You

One of the most important things that you will have on your bike are definitely the pedals, as these will not only help you pedal your bike and make it go forward but will also help you manoeuvre it in the air and on rough terrain. The first thing that you will have to ask […]

The Best Mountain Bike Pedals

If you are someone looking to purchase your first pair of mountain biking pedals, or just want to switch up the setup that you already have, this article is the right place for you. The pedals that you choose to run on your mountain bike will have a challenging job ahead of them as they […]

Everything You’ll Need To Know To Get Into Enduro Racing

Enduro first came about in the early 2010’s and has since become an extremely popular mountain bike discipline, quite possibly even one of the most favourite, representing the type of riding that most mountain bikers are already doing. What the Enduro discipline does is offer a technical but still accessible racing type for those mountain […]

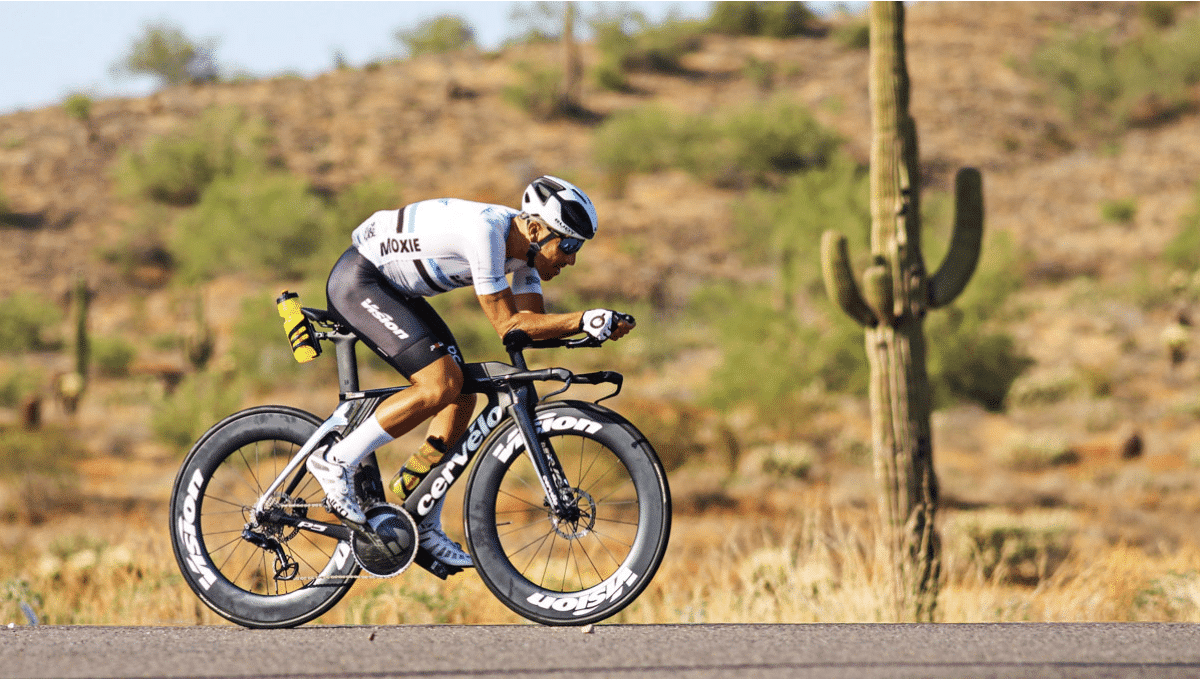

Make the Best of Cycling in Hot Weather With These Tips

If you compare running or any sports that don’t involve water with cycling in a heatwave, cycling is definitely the most pleasurable out of the bunch, as the higher speeds that you’ll be travelling at will provide a kind of cooling blanket of air over you. You do need to be careful though because this […]

The Best Mountain Bike Sunglasses

Having a great pair of sunglasses is definitely a must have for mountain bikers out there, for quite a number of reasons. Not only will these glasses obviously protect your eyes from the bright sunlight, but they’ll also help give you a more clever view of what’s to come on the trail, with less glare, […]

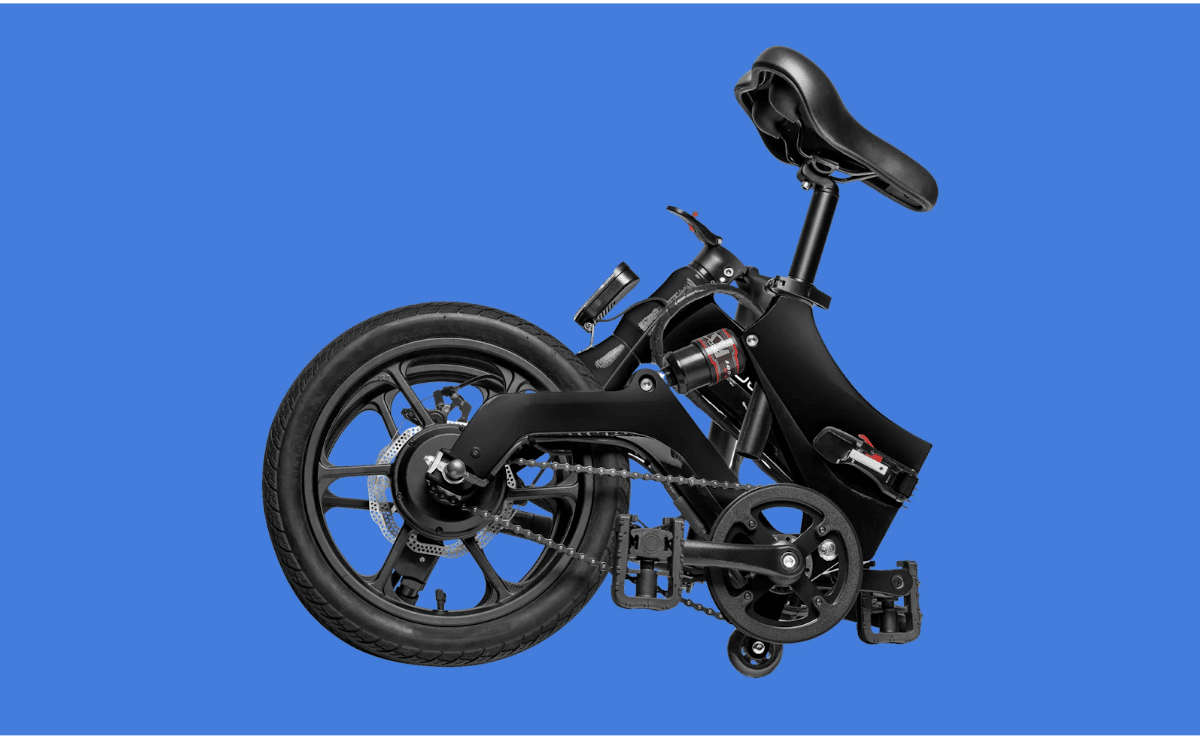

How to choose the best Electric Folding Bike

Having a great electric folding bike by your side is crucial to not only make your daily commutes a whole lot easier, thanks to its motor, but also make your journeys a lot more comfortable. Picking the right one for it is important as there are many characteristics that different electric folding bikes have that […]

The Top 3 Folding Electric Bikes of 2023

If you’re looking for a bike that doesn’t take up too much space in your home or your workplace but are still looking for that extra boost that the huge electric mountain bikes are able to give then these folding electric bikes may be just the thing that you are looking for. This type of […]